In Mid August Ramona and I drove our truck back down to Gairo to finish the installation work for the 17 pumps. We spent 2 nights in Dar es Salam where we picked up some of the Tanira manufactured pump parts we would need in Gairo, caught up with some friends and bought 3 weeks’ worth of groceries from one of the big new grocery stores in Dar. There is not too much available in Gairo for Mzungus.

After leavingDar we headed to Morogoro to pick up the remainder of the SWN pump parts we also needed, and then arrived at Gairo 2 hours later.

We had bought down to the Gairo office the laptop computer that had been back at Adra for a couple of weeks while we reset the settings back up for it operate correctly. The first day in Gairo we spent in the office instructing the staff how to use the computer, how to connect to the internet, send emails and check emails, put attachments on emails, sending pictures, and how to open and close the usual Office documents.

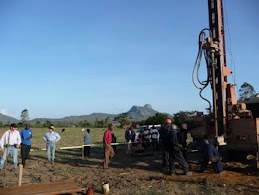

Over the next two weeks we installed all the pumps, generally 2-3 per day depending on how deep the pump inlet was set at. Due to Ross’ should injury and not able to lift anything heavy, the Project manager had arranged for a 2nd fundi to help us out with the installations. Nick was the one we had planned to us, but now we had Nick and Jonas. They were great to work with, learned fast, and were keen to work longer hours as required. It worked out best having Jonas there as well as now there are two people in Gairo who know in detail how to install these pumps, how to remove and repair them. The pumps are spread over 6 small villages around Gairo town. Nick and Jonas got to know the Village officers well while we were doing the installations so they have a good relationship set up now for the villagers to contact Nick if the pumps breakdown and need a service. So we think we have set up a very sustainable water supply. A typical installation would involve Nick Supervising, and doing the critical rod assemblies, Jonas doing the backup preparation and then up to 8 or so village males of various ages helping with the lifting of the rods to lower down the well, then about 20 or more other people watching and offering unendless suggestions. Often during the installations the people would be chatting back and forth with Nick and Jonas making jokes, some about us we gather, or singing a song (because they were happy they said at that time). This part of the project was the most rewarding. A very satisfying feeling that we were giving something to these people who basically have nothing and that the benefits to them were so obvious and to see how happy they were was truly a moving experience.

When we finished installing a pump, Nick or one of the village elders would get on the handle first and do the first pump strokes. We would take a picture of the first water coming out of that well. It would take a few strokes to get the water all the way up to the top, then it would start gushing out the outlet spigot. Clear cool water stroke after stroke. The mamas quickly appeared on the scene with their plastic buckets for filling. In some cases there were dozens of them with buckets awaiting water.

One of the wells was in Gairo town itself right outside our house we were staying in along one of the main back streets. We installed this pump early on as we wanted to be able to watch its use all the while we were there. Ironically enough as Gairo is a much bigger town than a small outlying village, we would have a lot of people to stop by and watch but no officials to come around and organise the local people. It is a shallow installation of 30 m, so it did not take long to install. Some of the neighbouring kids we had made good friends with back in Jan-Mar were there and they helped where they could. They are a lot of fun too. Once the pump was pumping water, the people seemed to come from every house we could see to get water. In Gairo, the water is normally a gravity fed system from up in the distant mountains. It is only turned on every 3rd day however as it is shared with other towns too. Water from this source is charged at 20 shillings (2 cents)per 20 liter bucket. But with this pump on their main back street, providing water at any time and it was free, this was a big deal for them. That poor pump was pumped from dawn to dusk every day by mamas or children. It seemed they were doing a pump stroke about every second, over 12 hours that is a lot of strokes. The pump is really designed to be used by a taller somewhat strong person that can do full strokes of the handle getting maximum water per stroke. However a lot of the women are shorter as are the kids and they would not have the arm strength to do full pump strokes time after time. Instead they would pull the handle down then lean over it with stiff arms and then bounce up and down on their feet (as their legs are stronger than their arms) to jiggle the handle up and down about 10% of its stroke. They can keep this up for ages albeit at a low water flow rate. We’d go out there time and time again to show them how to do full strokes to get full water flow and try to tell them it was better for the pump to do long slow strokes rather than these short rapid strokes. They would listen for a few minutes then 10 mins later you could come back and a new set of mamas or kids were on it doing the jiggle again. There were just too many different users over a full day to try to tell them all how to do it properly. After 2 days the Gairo pump stopped pumping water so we had to pull it out to see the problem. We could tell it was not working when we drove up to it as there were no people around using it. This was a very good learning exercise for Nick and Jonas. They were able pull the pump out and investigate where the problem was without Ross showing them where to look for the problem. The bottom cylinder internal plunger had unscrewed there by letting water back out the bottom again. We screwed it back together again tight with a big pipe wrench and reinstalled the pump. It worked well again and all the people came back with their buckets. 2 days later the same thing happened. Nick wanted to leave it not working for a few days to teach the people a lesson that they need to not do the jiggle stroke as that probably helped the bottom valve to unscrew. After we did pull the pump again and take the bottom cylinder apart and saw the same valve had come unscrewed I explained to Nick and Jonas there was a liquid called LockTite that was designed to keep threads from coming unscrewed. We had to search almost every hardware type store in Gairo but eventually found an equivalent product. We reassembled the valve and let it dry a day before reinserting the pump in the well. For the next 2 weeks after, till we left, the pump worked perfectly.

The SWN pumps had 4 m long rods that are made up of an outer PVC pipe 1-1/2” in diameter and a 3/8” diameter inner stainless steel suction rod. We noticed that over a 4 m section, the PVC was 10 mm longer than the steel rod. Hence over a 50 m length of assembled rods there was a 120 mm difference in the inner steel rods compared to the outer PVC pipe. This caused a problem and would not let the pump piston in the bottom cylinder have full travel. It didn’t matter on the shallower pumps but on these 50 m deep installations it was a problem. There were 4 of them too. We contacted the supplier in Morogoro and asked them to make up 4 short rods 100 mm long. When we added these short steel rods to the stack up of the 4 m long steel rods, that extra length let the pumps work properly giving full flow per stroke.

These 4 deep (50 m +) SWN pumps also had special bottom valves to allow then to pump from greater depths. After we had finished installing the deepest one at 57.5 m deep, when tested, even though the pump pumped water the action just felt wrong. Ross explained to Nick that we would have to pull the pump out to see what the problem was. We arranged to do this in a couple of days time as we knew it would be tricky. By now the 57.5 m of rods were also full of water and the whole set up was very heavy, 200 kg approx. We had to devise a slow and safe way to be able to lift these out using a lot of people to help lift. The problem was a manufacturing flaw. One of the steel fittings in the bottom valve had a bit of casting slag still in it that the valve was catching on. This was preventing the valve from moving up and down. We filed it off and the pump worked fine after that. It had taken 8 hours to pull the pump out, find the problem and repair it and then reassemble it back in the well again. Another good practice session for Nick and Jonas to learn from.

After we had finished the pump work, and the day before we left, the ADRA crew in Gairo had a little farewell meeting for us to say thank you for coming down to help them with their project and for getting to know each other. They presented us with some local gifts. A Kitanga for Ramona and a Maasai wrap for Ross. This was such a great moment to share with them.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment