Sunday, March 29, 2009

The Water Bringers

We have been told the local villagers from around the 6 villages we have been working in have given us a nick name. It is in Swahili, Wanaleta maji which means the Water Bringers. We probably have been a bit different to other people they may have seen over the years. A lot more hands on. We had gotten water in every well we drilled for them. Over the process of drilling the wells to installing the hand pumps that we have been out to each site numerous times to do something to the well, like build the slab, pump test it, bail water from it etc and each time some of the villagers had come out and seen us getting water out of these wells. So there must be a lot of local people who have seen us getting water from these wells and some of the different villagers have been talking to each other to come up with this name. Kind of Cute!

Installing the first hand pumps

Ramona and I had gone to Morogoro to buy enough parts to complete 3 of the 17 hand pumps needed. We installed these pumps in three different villages to give them a sample of what was to come. So last Sunday Ramona and I along with Nick our local helper and 3 of the local kids we have become friends with, loaded up the land cruiser and headed out to the first site. The pump sections are in 4 m lengths installed one at a time, lowering the assembly down the well 4 m further every time till the desired depth is reached. For each section, there is a stainless steel 10 mm inner sucker rod to connect up first then the outer PVC tube. It took a few trials to figure out how to do this efficiently and safely as once there were several lengths assembled it was too heavy to hold up by hand and the risk of dropping the assembly down the well was too high. The week before I had made up two sets of V blocks that would clamp around the outside of the PVC and act as stops to suspend the assembly at the top of the well so no one had to hold the weight. During assembly it became clear we needed a forked tool to hold the inner rods up above the PVC outer casing to allow the next inner rod to be connected to the lower inner rod. A trip back into Gairo to buy a piece steel and the use of a hack saw to make this tool solved the problem. After about 2 hours the first pump was installed and ready to go. I gave the handle a few pump up and downs and though I could hear water none came out. I gave it a few more with the same result. I started thinking, oh, what could be wrong? It is quite a simple set up. One of the village elders came over and we pumped a few more times and water started pouring out of the pump. Clear cool water just running out on to the pump slab we had made. The look on the villagers faces was one we’ll never forget. The word went around quickly and more and more people started coming out. Not that many but enough to make a crowd around the slab. The people were smiling, laughing and pointing at the water coming out. They quickly arranged for some buckets to put under the spigot to collect this valuable resource. Ramona said she was holding back tears from seeing the joy on these people’s faces. One mama with the usual baby on her back got on the pump and as she was pumping up and down you could see the baby’s head bobbing up and down like a ride on a bucking bronco. It made for a good video!We timed how long it took various people to fill a 20 liter ‘plastic’. A fit young male was about 1-1/2 min, an 8 yr old kid was about 2-1/2 mins and the mama with baby on back was 2 mins. This means on average it means they would pump about 600 lph while pumping.

After the first village and armed with the right tools now we went to the 2nd village to install the next pump. This pump was right beside a group of mud houses so there were plenty of people to come and see what we are doing. We had the pump installed in about 2 hours with a good sized group of watchers. Nick started pumping this pump for the first time. Just like the first one, after a few strokes, water started coming out of the spigot. More clear cool water. The people quickly saw what was happening and started bringing buckets of all colours pushing to get their bucket at the head of the queue. They all wanted a turn on the pump, talking loudly, laughing and smiling. One of the elder mamas there took charge of them and organised the empty buckets on the right and full ones on the right. We had our camera out to take pictures of different people and expressions. Once they saw this they all wanted their picture taken. Mzungu Mzungu cries were frequent to attract our attention. When you show them the picture on the camera screen, they laugh and scream and jostle around.

The third pump was not quite so dramatic. It was on a site that was out of sight of the local villagers so most of them did not know we were there. A few trickled down while we were there and got their buckets filled. One mama was on her way to the nearby water pit with green water in it when one of the guys called her over to get fresh water from the pump. This well is a Seep well, which is a name given to a well that has a low recharge rate, a lot lower than the above 600 lph. This means the people could be able to pump the well dry. We tested this out and after about 45 mins the pump stopped lifting water. We left it for 4 hours and when we came back there was plenty of more water again that had collected in the well. So these villagers may have to wait a while between pumping sessions it seems, but there will still be many buckets to pump from the well over a day.

After the first village and armed with the right tools now we went to the 2nd village to install the next pump. This pump was right beside a group of mud houses so there were plenty of people to come and see what we are doing. We had the pump installed in about 2 hours with a good sized group of watchers. Nick started pumping this pump for the first time. Just like the first one, after a few strokes, water started coming out of the spigot. More clear cool water. The people quickly saw what was happening and started bringing buckets of all colours pushing to get their bucket at the head of the queue. They all wanted a turn on the pump, talking loudly, laughing and smiling. One of the elder mamas there took charge of them and organised the empty buckets on the right and full ones on the right. We had our camera out to take pictures of different people and expressions. Once they saw this they all wanted their picture taken. Mzungu Mzungu cries were frequent to attract our attention. When you show them the picture on the camera screen, they laugh and scream and jostle around.

The third pump was not quite so dramatic. It was on a site that was out of sight of the local villagers so most of them did not know we were there. A few trickled down while we were there and got their buckets filled. One mama was on her way to the nearby water pit with green water in it when one of the guys called her over to get fresh water from the pump. This well is a Seep well, which is a name given to a well that has a low recharge rate, a lot lower than the above 600 lph. This means the people could be able to pump the well dry. We tested this out and after about 45 mins the pump stopped lifting water. We left it for 4 hours and when we came back there was plenty of more water again that had collected in the well. So these villagers may have to wait a while between pumping sessions it seems, but there will still be many buckets to pump from the well over a day.

Mikumi Wildlife Park

We are heading back to Arusha in a couple of weeks, for several months while we are waiting on pump parts to come in before we can carry on with the project. Hence we took the opportunity before leaving the area to go visit the Mikumi National park. It is straight south of us, not that far, but the dirt roads are not too good so it is best to drive east to Morogoro for 2 hours, then back south west to the park for 1-1/2 hours as that is all sealed road. The park is unique in that the sealed road actually drives right through the park from east to west and continues on to some other southern Tanzania towns. This means you can be driving along and come across a troop of baboons sitting on the road, or a herd or giraffes crossing the road. Elephants are plentiful as are impala along the road. Quite surreal. Big fines if you hit an animal through. There are speed bumps, vicious ones, all along the road so you can’t drive fast in most places anyway. We being tourists would stop to take pictures, where as the truckies and buses would get impatient with us and go around us at speed. The park on the north side of the road is about 1/3 of the total park, the other 2/3rds are to the south of the road but there is not much in the way of roads and tourist activities on that south side.The park headquarters is about ½ way along the road and then turn off to the north a few 100 m to go through their gate and access the interior of the park. It is all gravel sand roads in the park but in quite good condition. 4 WD not needed at all. You have to stay on the roads and are not allowed to get out of your car. This makes it a bit difficult to get some pictures at times. An open top vehicle would be an advantage. We just used out little Pajero. We hired a guide for $10 for the day to shows us what roads to drive on, and give us good information about the various animals.The park is quite flat with open long grassy areas and them some other places with more trees.

There are quite a few different animals to see. As well as the above are eland, warthogs, lions (we didn’t see any that day), leopards (though almost impossible to find in any park), lots of zebra and wildebeest, water buffalo, hippos, (who make the cutest deep based loud umph umph umph sound to each other), crocs, and lots of birds from small to medium size.

We stayed at a tiny hotel ( only 4 rooms) in the town of Mikumi right on the western side of the park outside the park boundary. Run by a Swiss-Tanzanian couple, great restaurant and bar. Real western food, oh Boy! There are a few safari lodges in the park where you may get big animals walking around outside your room. They are almost $500 a night however. Though very accessible, there are not many visitors to this park so you are not waiting behind other vehicles to see animals etc.

We drove around the park on Saturday and on Sunday we headed further west along the sealed road. The next big town is called Iringa and the Lonely Planet says it is a nice drive from the plains of Mikumi up a gorge 170 km to reach Iringa perched atop the hills. We didn’t have time to drive the whole way and still get back to Gairo at dusk, but drove most of it to see the scenery in the gorge. It is mostly too steep to farm so there are not many people living in that area and it is mostly forest and rocky bluffs with a decent sized river at the bottom. It was indeed a nice drive. The road even though sealed was in major need of repair. Dang!. There were so many broken down trucks or trucks in some form of accident, all the way along it. We’ll have to do it again and get all the way to Iringa next time.

There are quite a few different animals to see. As well as the above are eland, warthogs, lions (we didn’t see any that day), leopards (though almost impossible to find in any park), lots of zebra and wildebeest, water buffalo, hippos, (who make the cutest deep based loud umph umph umph sound to each other), crocs, and lots of birds from small to medium size.

We stayed at a tiny hotel ( only 4 rooms) in the town of Mikumi right on the western side of the park outside the park boundary. Run by a Swiss-Tanzanian couple, great restaurant and bar. Real western food, oh Boy! There are a few safari lodges in the park where you may get big animals walking around outside your room. They are almost $500 a night however. Though very accessible, there are not many visitors to this park so you are not waiting behind other vehicles to see animals etc.

We drove around the park on Saturday and on Sunday we headed further west along the sealed road. The next big town is called Iringa and the Lonely Planet says it is a nice drive from the plains of Mikumi up a gorge 170 km to reach Iringa perched atop the hills. We didn’t have time to drive the whole way and still get back to Gairo at dusk, but drove most of it to see the scenery in the gorge. It is mostly too steep to farm so there are not many people living in that area and it is mostly forest and rocky bluffs with a decent sized river at the bottom. It was indeed a nice drive. The road even though sealed was in major need of repair. Dang!. There were so many broken down trucks or trucks in some form of accident, all the way along it. We’ll have to do it again and get all the way to Iringa next time.

Saturday, March 7, 2009

Buckets and Buckets of Water

This week while the drillers were waiting for a resupply of materials, we went off to pump test some of the already finished bores. When we had first drilled each bore we had flow rate tested them to ensure they were yielding sufficient water before deciding to complete the bore or drill deeper. Now the goal of the pump testing was to pump a lot of water from the bore to see what level the bore could sustain a flow rate for. We estimated the village women could not pump faster than 500 lph or in their terms 25 buckets per hour. Hence we would start the pump testing with the QED Hammerhead pump (see www.qedenv.com)at 15 m deep below the top of the pump slab and let it pump to see if it could maintain that 500 lph flow rate or if it would draw the level down in the well to the level of the pump and the pump would stop and start as water trickled into the well. If it did this then we would lower the pump another 5 m and let it run again, if it drew it down again then we would lower the pump to 25 m etc. Once a sustainable level was found this told us how deep to set the hand pump intake valve in the bore. It was good for the bores to be pumped for a good amount of water too as this was the first time they had been really pumped so it was a chance for the bore to clean itself out. We also measured the water salinity before and after the pump test to see if there were any changes. The water clarity was also recorded before and after on a relative basis.

On the first bore we went to pump test it was at a site where we had encountered a good amount of water while drilling. We set the pump up and turned on the compressor. There were a few villagers and kids who had come out to watch as normal, but when they saw this clear water coming out of the hose and going onto the ground, they quickly organised the women to bring their 20 l plastic buckets to collect the water. Some even bought bigger containers to put water into as well, which made for a good picture when they put them on their heads to carry home. Even little girls of about 10-12 were carrying a 20 kg bucket of water on their head. How they balance them like that is a mystery. We pumped at 500 lph for over an hour filling buckets all the time. The women were so happy as this was close to their houses as compared to them having to walk a long way to get water from their normal source. Ramona started off holding the hose but then gave it to them to hold and fill their buckets. They were pleased to take charge. We’d get to a point where we would only have 3-4 buckets to go then two girls would show up with two more buckets and on it went like this. It was quite a good feeling to be able to help them like this and gave an indication of what it would be like when we actually mount the pumps on the wells for them to use the first time.

When we went to the next well and asked them if they had any plastic buckets they wanted to fill up, they quickly supplied them. By the time we got to the third bore in that village, the word had gotten around and women and girls with buckets were lining up.

We did 3 more bores in another village after that with a similar storey. Parts of the job like this are quite rewarding.

On the first bore we went to pump test it was at a site where we had encountered a good amount of water while drilling. We set the pump up and turned on the compressor. There were a few villagers and kids who had come out to watch as normal, but when they saw this clear water coming out of the hose and going onto the ground, they quickly organised the women to bring their 20 l plastic buckets to collect the water. Some even bought bigger containers to put water into as well, which made for a good picture when they put them on their heads to carry home. Even little girls of about 10-12 were carrying a 20 kg bucket of water on their head. How they balance them like that is a mystery. We pumped at 500 lph for over an hour filling buckets all the time. The women were so happy as this was close to their houses as compared to them having to walk a long way to get water from their normal source. Ramona started off holding the hose but then gave it to them to hold and fill their buckets. They were pleased to take charge. We’d get to a point where we would only have 3-4 buckets to go then two girls would show up with two more buckets and on it went like this. It was quite a good feeling to be able to help them like this and gave an indication of what it would be like when we actually mount the pumps on the wells for them to use the first time.

When we went to the next well and asked them if they had any plastic buckets they wanted to fill up, they quickly supplied them. By the time we got to the third bore in that village, the word had gotten around and women and girls with buckets were lining up.

We did 3 more bores in another village after that with a similar storey. Parts of the job like this are quite rewarding.

Wednesday, March 4, 2009

Quintessential Rural Tanzania

This one picture I realised after taking it shows so much by itself of rural life in Tanzania. It shows a woman walking home from a days work in the field, she is balancing the hoe on her head. She is pregnant and is carrying a child on her back as though the child was just another item to carry around while you do the days activities. There is another child following behind her. She probably has no money to buy a pair of shoes. The house she calls home is like the mud brick house in the back ground. The grass she is walking on has been grazed very short by the number of cows and goats they keep.

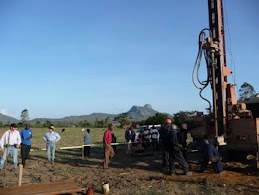

Coming to end of drilling phase

We are at the end of the drilling phase of the project. It has been a fun and very interesting three months. The drillers have been a great crew and we’ve had many a laugh along the way with them even though there are big language differences. It all adds to part of the fun. The next steps are to pump test the wells at various depths to see at what depth we will need to set the pump intake to allow a sustainable pumping rate that the villages will do with these hand pumps. Somewhere around 500 lph we think or in villager terms 25 buckets per hour. The driller told us they will pump a lot less than that as these women spend all their time talking!

Then after pump testing we need to finish off the concrete block slabs that we make to mount the hand pump on and it also serves as a elevated platform for the women to pump upon and keep the pump area out of the mud that will inevitably collect around any place where there is spilt water. This activity has been somewhat going on in parallel with the drilling. The local engineer has been mostly looking after this construction with Nik (see scratched Eye posting below) our neighbour and helper. The slabs are self draining and the water is ducted away a few meters to the low ground side of the slab to keep it away from the pumping area. Finally we put a wire fence around the slab a couple of meters out with a wire gate at the end to keep the livestock out and from contaminating the area. (The fence is made of 2” pipe for the posts and 1” pipe for the post stays and apparently there is a risk of someone stealing them for their scrap value.) Go figure.

The last step will be to actually install the pumps themselves. This will (should) be a short job but the procurement process in Tanzania is very slow. Let me say it starts with at least a 4 week process to first get a original proforma invoice from the supplier for the goods you want, then apply for a VAT tax exemption from the government Tanzania Revenue Authority. The proforma has to be an original no fax or email copies so you have to physically drive to that supplier to get the invoice even if they are a 10 hour drive away then after that is the procurement process, there are no credit card purchases, there are bank transfers but errors here are common. Cash is the medium of choice in a lot of cases so that means driving back to the supplier to give them the cash and hope they have the good in stock otherwise it is yet another trip back to them. (Yes you can tell the government makes it very difficult to make tax exempt purchases as they want to collect as much VAT as they can even through it means groups who are trying to help the people in their country are having to pay over 20% more for the goods they need to do their aid work in Tanzania.) Another Go figure!So there is no planned dates for when pump installation will happen which is a shame as the villagers are excited now about getting these water pumps working having seen us out drilling wells in their villages. When they don’t get it you can guess who will get the blame, yes the mzungus.

Bore water quality is becoming an issues, lab results show high chloride content, over the Tanzanian standard so this has to be considered somehow.

We have drilled 3 wells in each of 4 villages, drilled 1 and will repair two existing wells in a fifth village, 1 well each in the 6th and 7th villages. We were to do more but the budget can only go so far. Originally we were to drill on average 17 m deep wells using the information we had been given by the water diviner who had last year located the sites to drill at. However once we started we found this was far from sufficient and we had to drill on average 55 m depths. This is a much higher cost as the drilling costs roughly on average $100 per meter. After just 5 successful bores and 3 dry ones we were about to run out of money and have to stop. The operations manager of the drilling company we are using, who is from Oregon, paid us a visit and came up with a different and lower cost drilling method to suit us. This was to use a smaller diameter down hole hammer so it would penetrate a lot faster, using less labour time and fuel to drive it, plus since our holes are in rock, not clays he said we could not use PVC to case the hole, just leave the hole walls open and put the pump drop tube down the rock hole. He also said the water will be there just have confidence and drill deeper. This we did and had 100% success rate on all the future bores. Plus we were able to get the project budget revisited and dropped some other items that were no longer considered going to be of importance, so this freed up some funds to go to more drilling. Hence between all of this we got a 2nd wind to go drill more holes and managed to drill the above. So we should get to 17 of the original 22 water sites for the villagers. It has been a challenge from many angles but good to get through to be near the target.

It would have been good to use the philosophy we had for the last 3 villages in the earlier villages. In the early villages we were very conscious of the budget and shy about going deep. Hence some wells have low measured flow rates, below what we had hoped for but at that time it was all we could afford to do. Knowing now that there probably was more water deeper down it would have been good to try to get that. We drilled right at the end of the dry season so we concluded if a well had some water now, then it should yield more water in more wet seasons. Another theory we applied early on was if we measured a well to have a low inflow rate, (called a seep well) then we would drill a little deeper and put the pump inlet at the bottom. Then every night the well would fully recharge up to the static water level, and when the women come in the morning to get water they will fill the first 10-12 buckets from the water column in the bore alone, before having to wait and pump at the slower well recharge rate. Better than no water well at all we determined.

Ramona has done an excellent job of recording all details we use on site. We have to often go back through her notes and to recall what happened back then. She says she doesn’t understand drilling at all, but to read her notes implies the opposite. We made up an excel sheet that we updated as we finished a well. It records, well name location, projected depth, actual drilled depth if drilled, drilling method, drill costs, static water level, in flow rate, salinity level, pH, the type of pump we anticipate using on that bore and to what depth to set the pump inlet. It ends up being a lot of data.

It takes about 3 days to drill a well on average, a day’s travel to and from along these dirt roads/tracks, a day or a day and a half to drill depending on the depth and then a day to complete the well and pack up again. If it rains or we get a break down it adds to this time. So for the last 3 months we’d start the day with waking up to babies (there are many here) in neighbour houses crying, chooks cackling around outside the house, roosters having a crowing competition and some pigs screaming somewhere. Breakfast, then driving our little Pajero to the current site where the drillers were (they usually camped on site in the trucks), start drilling by 9-10 am, drill or work till about 6 -7pm and head back to the house, getting there at 7-7:30. Ramona packed us a picnic lunch every day with a couple of big bottles of cold water and a couple of sodas too. The drillers would do the actual drilling work or a few times we jump in and help lift rods around if one of the crew was away. Mostly though we were observing the drilling, measuring flow rates, static water levels, and making decisions as to keep drilling or when to stop drilling.

The weather for the most part has been fabulous. Glorious sunny days, too hot if anything, just light clothes and a big sun hat. Little wind. We did get 1-2 weeks of days where it would rain in the afternoon for a few hours then stop. This was not too big of a factor but what was a big factor was it making the ground too soft for the truck to move around on without getting stuck. For a while there we spent many hours every 3rd day digging one or other of the trucks out of the dirt. But then it cleared up again to more very nice weather. It made being on site quite pleasant some days. On the south and west are mountains to look at, there are big granite rock out crops spread around which are pretty and fun to spend a few hours climbing on. Some villages have more trees than others which makes them nice. Sometimes we were in or on the edge of a maize field or in the middle of grazing grounds with shepherds around with their live stock of cows and goats. (Alas there are no longer any wild animals around). There were always from a few to 100’s of spectators around. Lots of children(watoto menge!).

Then after pump testing we need to finish off the concrete block slabs that we make to mount the hand pump on and it also serves as a elevated platform for the women to pump upon and keep the pump area out of the mud that will inevitably collect around any place where there is spilt water. This activity has been somewhat going on in parallel with the drilling. The local engineer has been mostly looking after this construction with Nik (see scratched Eye posting below) our neighbour and helper. The slabs are self draining and the water is ducted away a few meters to the low ground side of the slab to keep it away from the pumping area. Finally we put a wire fence around the slab a couple of meters out with a wire gate at the end to keep the livestock out and from contaminating the area. (The fence is made of 2” pipe for the posts and 1” pipe for the post stays and apparently there is a risk of someone stealing them for their scrap value.) Go figure.

The last step will be to actually install the pumps themselves. This will (should) be a short job but the procurement process in Tanzania is very slow. Let me say it starts with at least a 4 week process to first get a original proforma invoice from the supplier for the goods you want, then apply for a VAT tax exemption from the government Tanzania Revenue Authority. The proforma has to be an original no fax or email copies so you have to physically drive to that supplier to get the invoice even if they are a 10 hour drive away then after that is the procurement process, there are no credit card purchases, there are bank transfers but errors here are common. Cash is the medium of choice in a lot of cases so that means driving back to the supplier to give them the cash and hope they have the good in stock otherwise it is yet another trip back to them. (Yes you can tell the government makes it very difficult to make tax exempt purchases as they want to collect as much VAT as they can even through it means groups who are trying to help the people in their country are having to pay over 20% more for the goods they need to do their aid work in Tanzania.) Another Go figure!So there is no planned dates for when pump installation will happen which is a shame as the villagers are excited now about getting these water pumps working having seen us out drilling wells in their villages. When they don’t get it you can guess who will get the blame, yes the mzungus.

Bore water quality is becoming an issues, lab results show high chloride content, over the Tanzanian standard so this has to be considered somehow.

We have drilled 3 wells in each of 4 villages, drilled 1 and will repair two existing wells in a fifth village, 1 well each in the 6th and 7th villages. We were to do more but the budget can only go so far. Originally we were to drill on average 17 m deep wells using the information we had been given by the water diviner who had last year located the sites to drill at. However once we started we found this was far from sufficient and we had to drill on average 55 m depths. This is a much higher cost as the drilling costs roughly on average $100 per meter. After just 5 successful bores and 3 dry ones we were about to run out of money and have to stop. The operations manager of the drilling company we are using, who is from Oregon, paid us a visit and came up with a different and lower cost drilling method to suit us. This was to use a smaller diameter down hole hammer so it would penetrate a lot faster, using less labour time and fuel to drive it, plus since our holes are in rock, not clays he said we could not use PVC to case the hole, just leave the hole walls open and put the pump drop tube down the rock hole. He also said the water will be there just have confidence and drill deeper. This we did and had 100% success rate on all the future bores. Plus we were able to get the project budget revisited and dropped some other items that were no longer considered going to be of importance, so this freed up some funds to go to more drilling. Hence between all of this we got a 2nd wind to go drill more holes and managed to drill the above. So we should get to 17 of the original 22 water sites for the villagers. It has been a challenge from many angles but good to get through to be near the target.

It would have been good to use the philosophy we had for the last 3 villages in the earlier villages. In the early villages we were very conscious of the budget and shy about going deep. Hence some wells have low measured flow rates, below what we had hoped for but at that time it was all we could afford to do. Knowing now that there probably was more water deeper down it would have been good to try to get that. We drilled right at the end of the dry season so we concluded if a well had some water now, then it should yield more water in more wet seasons. Another theory we applied early on was if we measured a well to have a low inflow rate, (called a seep well) then we would drill a little deeper and put the pump inlet at the bottom. Then every night the well would fully recharge up to the static water level, and when the women come in the morning to get water they will fill the first 10-12 buckets from the water column in the bore alone, before having to wait and pump at the slower well recharge rate. Better than no water well at all we determined.

Ramona has done an excellent job of recording all details we use on site. We have to often go back through her notes and to recall what happened back then. She says she doesn’t understand drilling at all, but to read her notes implies the opposite. We made up an excel sheet that we updated as we finished a well. It records, well name location, projected depth, actual drilled depth if drilled, drilling method, drill costs, static water level, in flow rate, salinity level, pH, the type of pump we anticipate using on that bore and to what depth to set the pump inlet. It ends up being a lot of data.

It takes about 3 days to drill a well on average, a day’s travel to and from along these dirt roads/tracks, a day or a day and a half to drill depending on the depth and then a day to complete the well and pack up again. If it rains or we get a break down it adds to this time. So for the last 3 months we’d start the day with waking up to babies (there are many here) in neighbour houses crying, chooks cackling around outside the house, roosters having a crowing competition and some pigs screaming somewhere. Breakfast, then driving our little Pajero to the current site where the drillers were (they usually camped on site in the trucks), start drilling by 9-10 am, drill or work till about 6 -7pm and head back to the house, getting there at 7-7:30. Ramona packed us a picnic lunch every day with a couple of big bottles of cold water and a couple of sodas too. The drillers would do the actual drilling work or a few times we jump in and help lift rods around if one of the crew was away. Mostly though we were observing the drilling, measuring flow rates, static water levels, and making decisions as to keep drilling or when to stop drilling.

The weather for the most part has been fabulous. Glorious sunny days, too hot if anything, just light clothes and a big sun hat. Little wind. We did get 1-2 weeks of days where it would rain in the afternoon for a few hours then stop. This was not too big of a factor but what was a big factor was it making the ground too soft for the truck to move around on without getting stuck. For a while there we spent many hours every 3rd day digging one or other of the trucks out of the dirt. But then it cleared up again to more very nice weather. It made being on site quite pleasant some days. On the south and west are mountains to look at, there are big granite rock out crops spread around which are pretty and fun to spend a few hours climbing on. Some villages have more trees than others which makes them nice. Sometimes we were in or on the edge of a maize field or in the middle of grazing grounds with shepherds around with their live stock of cows and goats. (Alas there are no longer any wild animals around). There were always from a few to 100’s of spectators around. Lots of children(watoto menge!).

Gifts for Drillers

One a recent trip to Dar es Salam we bought the drillers some gifts. The idea came from a week earlier we were out after dark digging one of the trucks out of soft dirt that it had gotten stuck in. The drillers were under the front axle trying to jack it up to put logs under the wheels. They were using their phones to provide some light. Ramona remembered we had out hiking head lamps in the Pajero and so got those two to lend to the drillers to work with. They were really pleased and asked the next day if they were a loan or could they keep them. We said they were a loan, but it gave us the idea of the gifts. So in Dar we bought each of the 4 of them a head lamp. Plus they have very little work safety equipment so we bought a pair of safety goggles, ear muffs and finally a set of long leather work gloves for each of them. The drilling truck has a welder on board as they often do welding of the steel surface casing or welding of a plate on top of the finished bore to stop kids throwing things down the well. They had no earth strap on the welder and had to tie/tack the earth wire to what they wanted to weld. So we bought an earth clamp too. When we came back and gave them to them they were so pleased, saying Acente over and over again. They use the items all the time now. The welder ‘Babu’ was quite excited to have a real earth clamp. He put it on the next day and then did some other repair on the welder too.

Subscribe to:

Posts (Atom)