Two other companies have very kindly donated equipment for the project here in Gairo. QED Environmental Systems Inc. of the USA, http://www.qedenv.com/ have donated a Hammerhead Pro® pneumatic pump with a 40 m tube set and fittings that we will use for bore flow rate testing. The bores need to be tested to ascertain they can sustain a flow rate that the villagers will likely to be pumping at. Hence this pump will be able to do that as well as pump at a much higher rate should we need to do more serious draw down testing at some locations to test aquifer flow capacities. The Hammerhead Pro® pump is a robust air driven pump for 100 mm or more bores and can accommodate sandy waters making it a good selection for the type of well studies we need to do.

TPS Pty Ltd of Australia , http://www.tps.com.au/ have donated a field water quality meter to allow testing of the bore water for salinity and pH on site. This will enable us to determine on site if there is a problem with these parameters in the water we are drilling for. The villagers tell Adra that salinity is a common problem around here. The meter is a AQUACPA® meter with calibration solutions.

Saturday, December 20, 2008

Started Water Well Drilling

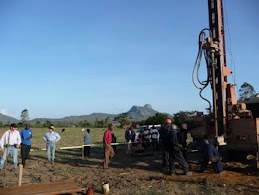

This week we made some good progress on the project. The drill rig arrived on Monday and started drilling Monday after noon. We had made a plan to drill 2 of the 22 bores before Christmas. The reason for this was that the site survey that had been done indicated the depth to the water table at each location. The average depth was 17 m according to this water diviner. Some were only 6 m and some were 30 meters and even one at 55 m. The drillers had had some experience in a nearby region and there they had said they had to go over 100 m deep to get water. This was causing us concern as if we had to drill to similar depths our budget would be blown in the first 6 bores and the villagers would not be happy with us.

The first well called for a depth of 22 m. We saw moist sand start to come up at 16 m. At 22 m there sand was still moist but very little water, we continued to 24 m deep assuming the 22 m depth was to the top of the water table. This was a little better but the driller was shaking his head that there was still no real water. By then it was late and they said let’s stop and see where the water table ends up at by the time we come back in the morning. The next morning using the new Dip meter kindly donated by Heron Instruments (www.heroninstruments.com) and a big bailer donated by Biolab (www.biolab.com.au), we made some level measurements. The water level had risen back all the way up to 7.3 m. We did some bail down tests to try to estimate recovery rates, but being an uncased hole it was difficult for the dip meter probe to not get covered in a slurry and start sounding off. The water flow rate still looked low however, so we decided to drill to 33 m. At around 28 m the materials coming out of the hole were now a real slurry showing it was getting quite wet down there. The driller would purge the hole completely every now and again with the compressor and a lot of water would fly out of the hole. We had a large crowd of spectators lined up outside the exclusion taped zone the drillers had put up. These were the local villagers hoping we would find water there for them to start using. When water would fly out of the hole they would laugh and jostle each other around with big smiles. The driller foreman started to dance a little jig too. At 33 m we stopped and did more drawdown tests and the water level meter showed there was a good amount of recharge coming into the well. Much more than what a villager on a hand pump could pump out so we were happy we had made the right call to drill deeper than the 22-24 m original target depth. The drillers then cased the hole by inserting 5” PVC casing and screen from the bottom to the top. Once the PVC was fully in, they filled the annulus between the bore ID and the PVC OD with fine gravel for the gravel pack then a cement plug on top of that up to the surface to prevent any surface water from running down the side of the PVC and contaminating the groundwater from the formation. The top was finished off with a 8” steel casing about 1.2 m long inserted around the PVC casing. We asked them to leave 400 mm of the steel casing sticking up above the ground, ready for us to build a concrete slab around it and mount the hand pump on top of that. Since we were not going to do the slab before Christmas, the drillers said what they normally do is weld on a plate on top of the 8” casing. This prevents children who think they are playing from coming and throwing rocks down the PVC and destroying the well.

The next day while the drillers were packing up and moving to the next site we had to drive into Morogoro to get the missing items for the house so that could be finished up ready for us to move into as we were still in this little hotel room which is getting uncomfortable as there is no where to spread our affairs out. The target depth at this second site was 15 m. It was in the same village as the first well, Ukwamani, but about 1 km (0.6 m) away. The drillers sent a text at noon saying they were at 15 m and the cuttings were dry, what do they do? We sent them to 24 m hoping it was the same situation as the first well. Later that afternoon they sent a text saying a small amount of water was flowing in at 16 m, but at 24 m it was hard rock that appeared unfractured. They were going to stop for the night and see where the water level would rise up to overnight. The next morning the water level had come up to 6.25 m from the surface. The driller was saying this was then the same water table as the first well. The flow rate into the well was still low so we decided to drill to 30 m to see if we could get into fractured rock as we had the day before. No such luck. At 30 m, still hard rock and no rock fractures were coming out of the bore only small sand like ground up rock particles. We stopped going deeper and they blew all the water and slurry out of the hole. We then did a remeasure of the water flow rate into the well by following the rising water level in the bore. It was the same as previous which showed that no water was coming in from these deeper zones but from that 16 m zone only. We calculated the rate to be about 200 liters per hour. The village women carry 20 liter buckets so that is 10 buckets an hour they could pump from this bore. I asked the driller if he thought the people could pump 10 buckets per hour. He started chuckling and replied with that these woman use the time at the well site as socialising. They pump a few strokes then stop to chat, then pump a few more strokes and so on, so no they would not be filling 10 buckets an hour. So taking that with a grain of salt, we decided to stop for this well and come back after Christmas to finish off developing and installing the PVC and steel top outer casing. The drillers packed up and late that afternoon caught busses out to their respective home towns for Christmas.

The next day with Jacob we went out to the list sites that we had not seen as yet and made notes about them as to their accessibility for the drill rig, or if any of the site markers the water diviner had placed were too close to each other to make it not worth putting in all wells at those locations. We also looked at the results of the drilling of the two wells and concluded that we would have to add an extra 8 m of depth on average to every bore we planned to drill to be more confident we would strike water and have a deep enough hole to fully insert the intake of pump drop tubes under several meters of water. We wanted to then see how this would affect the drilling budget. Jacob was also getting carpenters, masons and electricians into connect up the items we had bought in Morogoro to finish off the house. We hope it will be finished this weekend so we can move in when we come back after New Year.

We are off next week to visit the Selous Game Reserve and to Kilwa a coastal town to see some old Arabic ruins and hopefully find a resort or two to hang out in for a few days.

The first well called for a depth of 22 m. We saw moist sand start to come up at 16 m. At 22 m there sand was still moist but very little water, we continued to 24 m deep assuming the 22 m depth was to the top of the water table. This was a little better but the driller was shaking his head that there was still no real water. By then it was late and they said let’s stop and see where the water table ends up at by the time we come back in the morning. The next morning using the new Dip meter kindly donated by Heron Instruments (www.heroninstruments.com) and a big bailer donated by Biolab (www.biolab.com.au), we made some level measurements. The water level had risen back all the way up to 7.3 m. We did some bail down tests to try to estimate recovery rates, but being an uncased hole it was difficult for the dip meter probe to not get covered in a slurry and start sounding off. The water flow rate still looked low however, so we decided to drill to 33 m. At around 28 m the materials coming out of the hole were now a real slurry showing it was getting quite wet down there. The driller would purge the hole completely every now and again with the compressor and a lot of water would fly out of the hole. We had a large crowd of spectators lined up outside the exclusion taped zone the drillers had put up. These were the local villagers hoping we would find water there for them to start using. When water would fly out of the hole they would laugh and jostle each other around with big smiles. The driller foreman started to dance a little jig too. At 33 m we stopped and did more drawdown tests and the water level meter showed there was a good amount of recharge coming into the well. Much more than what a villager on a hand pump could pump out so we were happy we had made the right call to drill deeper than the 22-24 m original target depth. The drillers then cased the hole by inserting 5” PVC casing and screen from the bottom to the top. Once the PVC was fully in, they filled the annulus between the bore ID and the PVC OD with fine gravel for the gravel pack then a cement plug on top of that up to the surface to prevent any surface water from running down the side of the PVC and contaminating the groundwater from the formation. The top was finished off with a 8” steel casing about 1.2 m long inserted around the PVC casing. We asked them to leave 400 mm of the steel casing sticking up above the ground, ready for us to build a concrete slab around it and mount the hand pump on top of that. Since we were not going to do the slab before Christmas, the drillers said what they normally do is weld on a plate on top of the 8” casing. This prevents children who think they are playing from coming and throwing rocks down the PVC and destroying the well.

The next day while the drillers were packing up and moving to the next site we had to drive into Morogoro to get the missing items for the house so that could be finished up ready for us to move into as we were still in this little hotel room which is getting uncomfortable as there is no where to spread our affairs out. The target depth at this second site was 15 m. It was in the same village as the first well, Ukwamani, but about 1 km (0.6 m) away. The drillers sent a text at noon saying they were at 15 m and the cuttings were dry, what do they do? We sent them to 24 m hoping it was the same situation as the first well. Later that afternoon they sent a text saying a small amount of water was flowing in at 16 m, but at 24 m it was hard rock that appeared unfractured. They were going to stop for the night and see where the water level would rise up to overnight. The next morning the water level had come up to 6.25 m from the surface. The driller was saying this was then the same water table as the first well. The flow rate into the well was still low so we decided to drill to 30 m to see if we could get into fractured rock as we had the day before. No such luck. At 30 m, still hard rock and no rock fractures were coming out of the bore only small sand like ground up rock particles. We stopped going deeper and they blew all the water and slurry out of the hole. We then did a remeasure of the water flow rate into the well by following the rising water level in the bore. It was the same as previous which showed that no water was coming in from these deeper zones but from that 16 m zone only. We calculated the rate to be about 200 liters per hour. The village women carry 20 liter buckets so that is 10 buckets an hour they could pump from this bore. I asked the driller if he thought the people could pump 10 buckets per hour. He started chuckling and replied with that these woman use the time at the well site as socialising. They pump a few strokes then stop to chat, then pump a few more strokes and so on, so no they would not be filling 10 buckets an hour. So taking that with a grain of salt, we decided to stop for this well and come back after Christmas to finish off developing and installing the PVC and steel top outer casing. The drillers packed up and late that afternoon caught busses out to their respective home towns for Christmas.

The next day with Jacob we went out to the list sites that we had not seen as yet and made notes about them as to their accessibility for the drill rig, or if any of the site markers the water diviner had placed were too close to each other to make it not worth putting in all wells at those locations. We also looked at the results of the drilling of the two wells and concluded that we would have to add an extra 8 m of depth on average to every bore we planned to drill to be more confident we would strike water and have a deep enough hole to fully insert the intake of pump drop tubes under several meters of water. We wanted to then see how this would affect the drilling budget. Jacob was also getting carpenters, masons and electricians into connect up the items we had bought in Morogoro to finish off the house. We hope it will be finished this weekend so we can move in when we come back after New Year.

We are off next week to visit the Selous Game Reserve and to Kilwa a coastal town to see some old Arabic ruins and hopefully find a resort or two to hang out in for a few days.

The Move to the Gairo Water Project

Well what a week. We left Arusha at 7:45 on Tuesday morning 9th Dec, headed for Gairo. We were told it was 8-10 hours away. Our little truck was full to the brim and was weighted down. The first 100 km (60 m) were one little village (township) after another and for every town ship the sprinkle the road with speed bumps and judder bars. Makes driving at any speed impractical as you are always slowing down for these bumps. Some are not signed and some are, so sometimes you realise you are coming up on one all of a sudden and have to hit the brakes. Even then the suspension bottoms out. Thump! So the average speed we could do was about 40 mph. Then there are cops out in some of these towns as they put the speed at 30 kmph (18 mph) in weird places to, it seems catch people out. Someone had said it was near Christmas so the cops would be out enmass. Luckily though we saw many, we didn’t get pulled over. There are no obvious places to stop and eat at, I am sure there are places for locals to stop at but there is not much in the way of food for Mzungu’s. So we stopped for a bottle of coke at one place on the side of the road. You can’t take the bottles away so you have to stay there till you are finished. So no cold drinks in the truck.

The road from Arusha to Gairo is really taking the Arusha to Dar Es Salam road then turning off at a town called Chalinze before you get to Dar and head west on the Dar to Dodoma road. These are the only two sealed long roads in the country we think. Anywhere there are a lot of tourists (Arusha) or government workers (Dodoma and Dar) the roads are sealed, otherwise it is gravel or dirt. Even though it is probably highway one, there are very few cars on it, quite a lot of buses. Most local people do not own a car so buses are the method of travel. Some of these bus drivers are quite reckless. Passing on blind corners at high speed, or pulling back front of you before they have even finished passing you sometimes. Our truck has a digital display to show how many more kms we can go before refilling back up. We found out that there are not many gas stations on the road into Chalinze for the last 100 km and the display was showing we had 18 km left when we reached Chalinze, whew! This town is literally a T intersection and there are buses everywhere at all angles across the road. The local hawkers are out in force with trays and boxes of anything trying to sell to the bus passengers and Mzungu’s in a car are a great target. You have to work your way through the intersection between busses and hawkers with them leaning in towards any window offering their items. We get to a gas station and they are out of petrol, Gulp. The attendant points down the road and we head down there and find another one not far away that did have petrol. Whew again. The guy over fills it and dumps a pile of petrol on the ground.

We head west to Gairo. On the way we have to pass by the largest town in the region, Morogoro. About the same size as Arusha we think. Gairo is this tiny township on the road to Dodoma. From the road you can’t see much just a gas station and a few little African sell all stores(phone cards, water, soaps etc). We get to Gairo 11 hours after starting. It is dark now and naturally there are no street lights so we can’t see jack where to go. We call a the project manager Caleb and he comes to the gas station to lead us to our hotel. Hotel in Africa is a word that has quite different connotations to the western world. First once of the road it is all dirt roads with ditches on the side for water runoff. The hotel is a little 1 storey old plaster building wedged in between other anonymous buildings. It was dark and we are guided around to the back in a fenced off area for security. A girl comes out to greet us and show us the room Caleb had prearranged. It is clean and tidy. The toilet won’t flush, there is no hot water that night. She brings in a bucket of water and points to it and the toilet. In Gairo there is almost no English spoken at all unlike Arusha. No tourists ever come here as there is nothing here for them to do. It is about a town of 30-40,000 and we find out we are the only Mzungu’s here the next day. We get up the next morn and there is hot water in the shower then, which is a shower head next to the toilet bowl, no walls for it or anything. There is no breakfast to be had. We had only bought into the room a few clothes leaving the truck full still as we were planning to take it to the house ADRA had ‘set’ up for us the next day. On the way into Gairo we got a hole in the exhaust and the truck was making a louder than normal noise. Here I am thinking, there is no Mitsubishi dealer in Tanzania and to get an exhaust may involve a drive back to Dar (4-5 hrs) and try to get an exhaust imported from Kenya or South Africa possibly and that would only take 3 months is my guess. Not good. Not happy Jan! Caleb had asked his engineer Jacob to come over at 9am. So we get in the truck with him and he shows us where to drive. We drive to a bus station we think or a bus repair station. Jacob starts talking to some local young guys about the exhaust. They point across the street (dirt road) to where I can see and Oxy Acetylene set out on the street. So we drive over there and Jacob talks to that guy. The guy can weld a patch on for a price. Jacob bargains him down from $8 to $6. So OK he starts. First he finds a bit of wire lying on the ground, then a bit of rustyish painted sheet metal off something else. Cuts it into a square big enough to cover the hole. Then gets down under the car and welds it on with no face mask or eye protection. After he had finished I started the car and it sounded completely normal. I could not feel any leaks around the patch either. So off we went. It is a temporary fix for a few months hopefully but will give us time to get back to Arusha in Jan hopefully.

Then Jacob takes us to the Adra office which is down a rough dirt road packed with more shops along the side selling more phone cards, water, shoes, bags, clothes some fruit, hair dressers, very basic hardware stores. All the while everyone we pass is staring at the Mzungus in the truck driving through their town. People are friendly however, they wave and smile if you do the same to them. The kids come running and waving. The Adra office is a rented 4 room house, no running water, no kitchen, just 4 empty rooms. Our house which has been specially prepared for us is right opposite over the dirt road. Jacob gets the keys and he and the secretary Keja give us a quick tour. It does have 3 bedrooms, again just empty rooms, but it does have a toilet/shower like the hotel, and a kitchen. There is no running water at all in it. Gairo was originally planned as a town of 10,000 people and what infrastructure was put in back in the 70’s was for 10,000 people. Now there are 30-40K completely overwhelming any infrastructure. So no houses are allowed to have water plumbed to them. The water can only begotten from public taps (water points) set about every 500 m along the street. The house was meant to be supplied with a bed and mattress, table and chairs, water, oven, fridge, mosquito nets. None of this is there (some we knew about from last week and so Musa from VSA had said he would bring some of it down in his Hilux truck this next week)and so we can’t move in. And to get it ready was no small matter, some extensive plumbing is required. On a humerous note, Jacob had applied to the area water commissioner to get an exemption and be allowed to run water into this house because the Mzungu’s are coming soon! And though it had taken a while due to the bureaucracy, he had gotten the exemption through. The local commissioner had been stalling and stalling but Caleb and Jacob had taken it to the regional commissioner saying the experts from overseas were coming to help the people in the local villages with their water supply and hence they needed this house plumbed with water to make them comfortable to stay here. He had agreed and directed the local commissioner to grant the permit. We are learning African politics is a very delicate thing. So now they are having to dig up 300 m of dirt road thru peoples yards (if you can call a dirt strip between one mud brick house and another a yard) to tie a poly line into a main line to a water point and bring water to this house. Today there were two young girls out with hoes digging this 8 deep x 8 inch wide trench through the red dirt.

Jacob is changing out the Asian toilet to a English toilet bowl too. But we can’t move in till the house is ready. Jacob can’t do the plumbing till he gets cash from Caleb to go buy the necessary fittings. We let Max know back at Adra in Arusha that the house is a long way from ready as we had been told it was. So we are stuck at this little hotel, jammed in with no room to spread anything out. Our excess items we off loaded into one of the empty rooms in the Adra office till the house is ready. Our enthusiasm waned considerably early this week. Poor Ramona was way out of her comfort zone. She likes to be organised and there is no way anything can be organised at the moment. Quite frustrating to say the least.

There is another short term volunteer Ben from Melbourne who came to ADRA under his own steam and we sort of nabbed him to come and help us on this Gairo project for Jan and Feb . He is part way through an Env science degree and is an eager beaver to get into some water well work. He is short of funds as he is finding out Africa is not cheap for non locals. So he is going to stay in our house (when it is ready) too. He too is at the hotel at the moment. Luckily the hotel for his room is only $10 per night and meals are about $2 per person at night. Beer s $1.50 a stubbie.

Since there are no Mzungu’s in Gairo there is only local food available. The local people eat ground up maize as a paste (called Ogali) with their fingers and a few vegetables like spinach, or carrots. Not much else. So this means for westerners this is a food deficient town. I asked Keja where to buy a snickers bar yesterday showing her one. She looked at it and mispronounced the name and said she had never seen one before, and what was it? There is no bread, no jam, no cereal, no canned fruit or veges of any type, no candy, hardly any juice, no potatoes, apples or other fruit other than bananas, pine apples and mangoes. So on day 2 we had to drive back to Morogoro to fill the truck up with western food to last us a week or more. Ben came too. That was $200 of items from a small corner store which was the only real grocery store in Morogoro. The Indian owners were happy with us. Then we had to get basics for the house like 3 plates, KFS, pots, toaster, dish rack, chopping board, electric kettle (to make hot bathing water), can opener, candles and matches for when the power goes out, cleaners and such. This is going beyond what a volunteer is meant to do but anything to make this place more livable was our thought.

Today Friday was Caleb’s meeting with the regional politicians. It was to announce the kick off of a HIV/Aids education program that Adra is also doing down here. It is a big project so a big deal for this region. They had invited a lot (about 40) of community leaders to this meeting to inform them of this program and the big cheese regional commissioner was there to do the official kick off. He has his entourage of staff as well so it was a big deal meeting. It was held in a school hall. Caleb and the politicians sat on a table on the stage and the community people say in rows of chairs on the main floor. We were asked to sit in the front row. Ben, Ramona and myself. Jacob sat with us to translate for us. This was true Africa style meeting. No western influences here at all. When the regional commissioner walked in in his flash suit the community leaders started chanting in Swahili, it might have been his name or the name of the president or such we could not tell. They have regions here like states, then districts like counties then wards like individual villages. So there was the regional commissioner (a appointed position not an elected position), the district commissioner, the ward chairman and secretary, the local police chief from Gairo and a few others we are not sure who. Caleb got up and gave a speech and started off telling the community about Adra and its goals, then who was on the Adra team here in Gairo from Keja the secretary to his own role and then he points at us and introduces Ben from Australia as a expert who has come to help the people out to get their water, then he moves on to Ramona saying some thing similar, we could hear him say America, Australia in his speech. Then he moves on to me and says a bunch more. Jacob was translating by them. Caleb was saying the Mzungus have come to save the project, by doing some of the work ourselves now like pump testing and pump installations we were saving money and saving the project. That we were experts and the community needed to treat us as special as we were here to help them out. We had to stand while they clapped for us. Caleb later said after the dignitaries’ were gone the community leaders were coming up to him saying send the Mzungus out to our ward please. Some women had traditional style clothes on or the more senior women had pretty outfits on. I must admit I started off the meeting with scepticism about these big politicians as you hear so much about the corruption in politics, but this guy was very earnest in his talk. He spoke about the problem aids was for his region and how it was spreading and they as community leaders were tasked with getting the education around to try to control this epidemic. He spoke of Adra and how grateful the region was that outside donors we coming to help them, but please for Adra to make sure that the money as put to the correct use and not siphoned off as some unscrupulous groups do. Needless to say he got rounds of claps too. He had each of the 40 leaders stand up and say their name and what they do in the community which was a nice touch to make the people feel more personal I think.

With Jacob we drove around in our truck to some of the sites we are to drill at and install water pumps. He said lets go to the furtherest one first so you can see what the drillers will have to face when they get here. The drillers were due in a couple of days. So we dove about 12 km out through the scrub on a dirt trail up hill and down dale, through washed out gullies, along sand tracks, through house back yards. Kind of fun really to do some off road driving. It is hot so it is all dry at the moment so no mud to get stuck in. Along the way Jacob was telling us about the area. He pointed out that the villagers use local wood to cook their meals every day. These are people that have rarely seen a car, probably have never been more than 10 m from their home. The education level is quite low. There is constant cutting of braches and trees to get firewood. An absolute disaster in the making. The place will turn into a desert. But what else can they do. They do not deal in cash, so they can’t go to town (even if they could do that) to buy a gas bottle for a stove. The govt does not run electricity out to their villages.

Saturday. There is a small rock mountain out the back of Gairo and we had the day to spare so we put on our boots and went and climbed to the top of it. It has two peaks really the front and back peak. We didn't have time to do both. It afforded a good view of the Gairo town and plains below way off into the distance. We could see other similar rock outcrops around too, which we may go explore one day if we get time.

Today Sun 14th we met with the driller foreman who had come in a few days late. The rig is to arrive tomorrow. We took him on a drive back out to the same sites and a few more so he could access the route to get their big 20 ton truck out to these sites. SO another 4 hours of driving around the dirt tracks, it had rained this afternoon so there were some wet roads and streams to cross this time. Quite fun this type of driving. On the way back on the dirt road there were some pot holes and there was a family out there scooping water out of the pot holes and putting it into buckets to take to their house. This grey dirty water was that important to them. Jacob said they don’t even boil it before drinking it. The Adra training group try to inform the people about the importance of boiling it at least but trying to change long habits is very difficult and most of the time unsuccessful. However boiling the water would take more cutting down of more trees as well. So we have to be careful in the aims of the project as to fix one problem could well be making another one. It takes so long for trees to grow back so this is not a sustainable practise. We have seen no forestry plots to grow trees at all so far.

The road from Arusha to Gairo is really taking the Arusha to Dar Es Salam road then turning off at a town called Chalinze before you get to Dar and head west on the Dar to Dodoma road. These are the only two sealed long roads in the country we think. Anywhere there are a lot of tourists (Arusha) or government workers (Dodoma and Dar) the roads are sealed, otherwise it is gravel or dirt. Even though it is probably highway one, there are very few cars on it, quite a lot of buses. Most local people do not own a car so buses are the method of travel. Some of these bus drivers are quite reckless. Passing on blind corners at high speed, or pulling back front of you before they have even finished passing you sometimes. Our truck has a digital display to show how many more kms we can go before refilling back up. We found out that there are not many gas stations on the road into Chalinze for the last 100 km and the display was showing we had 18 km left when we reached Chalinze, whew! This town is literally a T intersection and there are buses everywhere at all angles across the road. The local hawkers are out in force with trays and boxes of anything trying to sell to the bus passengers and Mzungu’s in a car are a great target. You have to work your way through the intersection between busses and hawkers with them leaning in towards any window offering their items. We get to a gas station and they are out of petrol, Gulp. The attendant points down the road and we head down there and find another one not far away that did have petrol. Whew again. The guy over fills it and dumps a pile of petrol on the ground.

We head west to Gairo. On the way we have to pass by the largest town in the region, Morogoro. About the same size as Arusha we think. Gairo is this tiny township on the road to Dodoma. From the road you can’t see much just a gas station and a few little African sell all stores(phone cards, water, soaps etc). We get to Gairo 11 hours after starting. It is dark now and naturally there are no street lights so we can’t see jack where to go. We call a the project manager Caleb and he comes to the gas station to lead us to our hotel. Hotel in Africa is a word that has quite different connotations to the western world. First once of the road it is all dirt roads with ditches on the side for water runoff. The hotel is a little 1 storey old plaster building wedged in between other anonymous buildings. It was dark and we are guided around to the back in a fenced off area for security. A girl comes out to greet us and show us the room Caleb had prearranged. It is clean and tidy. The toilet won’t flush, there is no hot water that night. She brings in a bucket of water and points to it and the toilet. In Gairo there is almost no English spoken at all unlike Arusha. No tourists ever come here as there is nothing here for them to do. It is about a town of 30-40,000 and we find out we are the only Mzungu’s here the next day. We get up the next morn and there is hot water in the shower then, which is a shower head next to the toilet bowl, no walls for it or anything. There is no breakfast to be had. We had only bought into the room a few clothes leaving the truck full still as we were planning to take it to the house ADRA had ‘set’ up for us the next day. On the way into Gairo we got a hole in the exhaust and the truck was making a louder than normal noise. Here I am thinking, there is no Mitsubishi dealer in Tanzania and to get an exhaust may involve a drive back to Dar (4-5 hrs) and try to get an exhaust imported from Kenya or South Africa possibly and that would only take 3 months is my guess. Not good. Not happy Jan! Caleb had asked his engineer Jacob to come over at 9am. So we get in the truck with him and he shows us where to drive. We drive to a bus station we think or a bus repair station. Jacob starts talking to some local young guys about the exhaust. They point across the street (dirt road) to where I can see and Oxy Acetylene set out on the street. So we drive over there and Jacob talks to that guy. The guy can weld a patch on for a price. Jacob bargains him down from $8 to $6. So OK he starts. First he finds a bit of wire lying on the ground, then a bit of rustyish painted sheet metal off something else. Cuts it into a square big enough to cover the hole. Then gets down under the car and welds it on with no face mask or eye protection. After he had finished I started the car and it sounded completely normal. I could not feel any leaks around the patch either. So off we went. It is a temporary fix for a few months hopefully but will give us time to get back to Arusha in Jan hopefully.

Then Jacob takes us to the Adra office which is down a rough dirt road packed with more shops along the side selling more phone cards, water, shoes, bags, clothes some fruit, hair dressers, very basic hardware stores. All the while everyone we pass is staring at the Mzungus in the truck driving through their town. People are friendly however, they wave and smile if you do the same to them. The kids come running and waving. The Adra office is a rented 4 room house, no running water, no kitchen, just 4 empty rooms. Our house which has been specially prepared for us is right opposite over the dirt road. Jacob gets the keys and he and the secretary Keja give us a quick tour. It does have 3 bedrooms, again just empty rooms, but it does have a toilet/shower like the hotel, and a kitchen. There is no running water at all in it. Gairo was originally planned as a town of 10,000 people and what infrastructure was put in back in the 70’s was for 10,000 people. Now there are 30-40K completely overwhelming any infrastructure. So no houses are allowed to have water plumbed to them. The water can only begotten from public taps (water points) set about every 500 m along the street. The house was meant to be supplied with a bed and mattress, table and chairs, water, oven, fridge, mosquito nets. None of this is there (some we knew about from last week and so Musa from VSA had said he would bring some of it down in his Hilux truck this next week)and so we can’t move in. And to get it ready was no small matter, some extensive plumbing is required. On a humerous note, Jacob had applied to the area water commissioner to get an exemption and be allowed to run water into this house because the Mzungu’s are coming soon! And though it had taken a while due to the bureaucracy, he had gotten the exemption through. The local commissioner had been stalling and stalling but Caleb and Jacob had taken it to the regional commissioner saying the experts from overseas were coming to help the people in the local villages with their water supply and hence they needed this house plumbed with water to make them comfortable to stay here. He had agreed and directed the local commissioner to grant the permit. We are learning African politics is a very delicate thing. So now they are having to dig up 300 m of dirt road thru peoples yards (if you can call a dirt strip between one mud brick house and another a yard) to tie a poly line into a main line to a water point and bring water to this house. Today there were two young girls out with hoes digging this 8 deep x 8 inch wide trench through the red dirt.

Jacob is changing out the Asian toilet to a English toilet bowl too. But we can’t move in till the house is ready. Jacob can’t do the plumbing till he gets cash from Caleb to go buy the necessary fittings. We let Max know back at Adra in Arusha that the house is a long way from ready as we had been told it was. So we are stuck at this little hotel, jammed in with no room to spread anything out. Our excess items we off loaded into one of the empty rooms in the Adra office till the house is ready. Our enthusiasm waned considerably early this week. Poor Ramona was way out of her comfort zone. She likes to be organised and there is no way anything can be organised at the moment. Quite frustrating to say the least.

There is another short term volunteer Ben from Melbourne who came to ADRA under his own steam and we sort of nabbed him to come and help us on this Gairo project for Jan and Feb . He is part way through an Env science degree and is an eager beaver to get into some water well work. He is short of funds as he is finding out Africa is not cheap for non locals. So he is going to stay in our house (when it is ready) too. He too is at the hotel at the moment. Luckily the hotel for his room is only $10 per night and meals are about $2 per person at night. Beer s $1.50 a stubbie.

Since there are no Mzungu’s in Gairo there is only local food available. The local people eat ground up maize as a paste (called Ogali) with their fingers and a few vegetables like spinach, or carrots. Not much else. So this means for westerners this is a food deficient town. I asked Keja where to buy a snickers bar yesterday showing her one. She looked at it and mispronounced the name and said she had never seen one before, and what was it? There is no bread, no jam, no cereal, no canned fruit or veges of any type, no candy, hardly any juice, no potatoes, apples or other fruit other than bananas, pine apples and mangoes. So on day 2 we had to drive back to Morogoro to fill the truck up with western food to last us a week or more. Ben came too. That was $200 of items from a small corner store which was the only real grocery store in Morogoro. The Indian owners were happy with us. Then we had to get basics for the house like 3 plates, KFS, pots, toaster, dish rack, chopping board, electric kettle (to make hot bathing water), can opener, candles and matches for when the power goes out, cleaners and such. This is going beyond what a volunteer is meant to do but anything to make this place more livable was our thought.

Today Friday was Caleb’s meeting with the regional politicians. It was to announce the kick off of a HIV/Aids education program that Adra is also doing down here. It is a big project so a big deal for this region. They had invited a lot (about 40) of community leaders to this meeting to inform them of this program and the big cheese regional commissioner was there to do the official kick off. He has his entourage of staff as well so it was a big deal meeting. It was held in a school hall. Caleb and the politicians sat on a table on the stage and the community people say in rows of chairs on the main floor. We were asked to sit in the front row. Ben, Ramona and myself. Jacob sat with us to translate for us. This was true Africa style meeting. No western influences here at all. When the regional commissioner walked in in his flash suit the community leaders started chanting in Swahili, it might have been his name or the name of the president or such we could not tell. They have regions here like states, then districts like counties then wards like individual villages. So there was the regional commissioner (a appointed position not an elected position), the district commissioner, the ward chairman and secretary, the local police chief from Gairo and a few others we are not sure who. Caleb got up and gave a speech and started off telling the community about Adra and its goals, then who was on the Adra team here in Gairo from Keja the secretary to his own role and then he points at us and introduces Ben from Australia as a expert who has come to help the people out to get their water, then he moves on to Ramona saying some thing similar, we could hear him say America, Australia in his speech. Then he moves on to me and says a bunch more. Jacob was translating by them. Caleb was saying the Mzungus have come to save the project, by doing some of the work ourselves now like pump testing and pump installations we were saving money and saving the project. That we were experts and the community needed to treat us as special as we were here to help them out. We had to stand while they clapped for us. Caleb later said after the dignitaries’ were gone the community leaders were coming up to him saying send the Mzungus out to our ward please. Some women had traditional style clothes on or the more senior women had pretty outfits on. I must admit I started off the meeting with scepticism about these big politicians as you hear so much about the corruption in politics, but this guy was very earnest in his talk. He spoke about the problem aids was for his region and how it was spreading and they as community leaders were tasked with getting the education around to try to control this epidemic. He spoke of Adra and how grateful the region was that outside donors we coming to help them, but please for Adra to make sure that the money as put to the correct use and not siphoned off as some unscrupulous groups do. Needless to say he got rounds of claps too. He had each of the 40 leaders stand up and say their name and what they do in the community which was a nice touch to make the people feel more personal I think.

With Jacob we drove around in our truck to some of the sites we are to drill at and install water pumps. He said lets go to the furtherest one first so you can see what the drillers will have to face when they get here. The drillers were due in a couple of days. So we dove about 12 km out through the scrub on a dirt trail up hill and down dale, through washed out gullies, along sand tracks, through house back yards. Kind of fun really to do some off road driving. It is hot so it is all dry at the moment so no mud to get stuck in. Along the way Jacob was telling us about the area. He pointed out that the villagers use local wood to cook their meals every day. These are people that have rarely seen a car, probably have never been more than 10 m from their home. The education level is quite low. There is constant cutting of braches and trees to get firewood. An absolute disaster in the making. The place will turn into a desert. But what else can they do. They do not deal in cash, so they can’t go to town (even if they could do that) to buy a gas bottle for a stove. The govt does not run electricity out to their villages.

Saturday. There is a small rock mountain out the back of Gairo and we had the day to spare so we put on our boots and went and climbed to the top of it. It has two peaks really the front and back peak. We didn't have time to do both. It afforded a good view of the Gairo town and plains below way off into the distance. We could see other similar rock outcrops around too, which we may go explore one day if we get time.

Today Sun 14th we met with the driller foreman who had come in a few days late. The rig is to arrive tomorrow. We took him on a drive back out to the same sites and a few more so he could access the route to get their big 20 ton truck out to these sites. SO another 4 hours of driving around the dirt tracks, it had rained this afternoon so there were some wet roads and streams to cross this time. Quite fun this type of driving. On the way back on the dirt road there were some pot holes and there was a family out there scooping water out of the pot holes and putting it into buckets to take to their house. This grey dirty water was that important to them. Jacob said they don’t even boil it before drinking it. The Adra training group try to inform the people about the importance of boiling it at least but trying to change long habits is very difficult and most of the time unsuccessful. However boiling the water would take more cutting down of more trees as well. So we have to be careful in the aims of the project as to fix one problem could well be making another one. It takes so long for trees to grow back so this is not a sustainable practise. We have seen no forestry plots to grow trees at all so far.

Sunday, December 7, 2008

Road Trip to Babati

We decided to go out west for a few days to another town called Babati where there is a similar project being undertaken but in a bigger way than our Gairo project. We thought by watching what they were doing we would get some good information to take down for our project in Gairo. We took Peter, a local person from ADRA, who has been helping us with various projects at ADRA. Peter has also been teaching us Swahili. In Babati they are installing new wells and refurbishing old wells that are no longer being used for a variety of reasons, including a missing pump, a broken pump, a broken concrete slab or no water there anymore. In Gairo we are to install new wells only as there are no other older ones there. We drove through Arusha and stopped off at Musa’s office and told him we were heading out there. He said, “ you are not taking your truck on that road are you?” The road is very bad. But we went anyway. Babati is about 200 km (120 miles) west of Arusah. The first 120 km are also on the way to the big game parks, so the roads are nicely sealed. However once past the game parks and tourists area, there is no longer “an international need” to go there, so the tarmac disappears and it is a gravel and dirt road. It looks smooth from a distance, but the corrugations and potholes make it a real bone shaker. About 20 km/hr was all we could do in many places. It is wide enough for 2 lanes but one drives anywhere to find the smoothest path. Off to the right for a few 100 meters, then switch over to the left for the next few 100 meters, then off the road on the shoulder for a bit more. There are a few buses coming through all the time and they just fly by bouncing around. Every now and then we came across one fixing a puncture or broken axel possibly. We could also see some trucks driving on a parallel-ish dirt path off to the right in the scrub. I asked Peter what that was and he said we should not drive there because it was single lane, and we couldn’t see far enough though the scrub plus the trucks drive fast there. But after about another 30 mins of unending shaking Peter said, “OK, go to the dirt road”. It was such a relief, we could get up to about 40 km/hr in places! In other places, we almost came to a stop to cross some washed out crevice. But it was a lot faster. The track passed through the back of houses that were on the official road side. I couldn’t tell sometimes if we were on a dirt road or driving through some ones yard. The locals would stare at our truck driving along this path. Luckily we didn’t meet many big trucks on this dirt path and we got to Babati just on dusk, having taken about 4 hours to drive the 200 km.

The next day the project leader there and a few others piled us into their Landcruiser and we headed out to the rural villages where the work was being done. She said our little truck may not handle these roads too well. We soon found out why very quickly! They are no roads, only dirt tracks through the scrub and trees that the locals use. No government assistance to make any roads for the people at all. It was dry so it was not too bad, but can’t imagine what would happen when it is wet. The first site we visited was a new well site being drilled. To get a picture of where these are installed, don’t think of a well being installed on a street corner or such but picture an area with rolling hills, no fences anywhere and a well just drilled at some location in a field. (The well sites had previously been sited by a water diviner.)

This location was on the side of a hill. The drillers were a contracting company from Arusha. They were using an older style rig that used percussion or cable tool method. This rig repetitively lifts and drops a weight onto a drill bit down the hole. The bit crushes the rock down to sand like particles. Then every 10 mins of so, they pull the weight and bit out of the hole, lower down a long steel bailer to surge up and down, partially filling it with the newly crushed sand. Then they lift that out and tip it upside down using the winch to dump its contents on the ground. They do this a few times then go back to drilling again. The method is slow compared to other drilling methods but it is lower cost and does not require large air compressors and such. They were down about 30 m deep when we arrived.

The drillers stay on site. They put up a small tent with a “bed” covered by a mosquito net and cook their meals over an open fire. At this time of year it is quite warm but not too hot.

We stayed there about 2 hours to watch their operation. That drilling method was new to us (because it’s not often used in Australia anymore)but the other office staff had seen it all before so they were doing other activities while we watched.

Next we were taken over to a natural spring that had a small flow of coming water from it. It was in some trees on the side of a hill just up from the bottom of the gulley. There was a local woman there getting water in some buckets to take back up the hill to her house, but we had no idea how far she lived from there. It could have been several kilometres away and she was carrying the water. The water out of the spring was clean it seemed but when it ran into a little pool where the buckets were being filled from, it got a bit cloudy. The woman was asked if the water was boiled before it was drank. She said some do and some don’t.

An old abandoned site was the next visit. This was a small (2 m diameter) domed slab that used to have a pump on it, but the pump was gone and a rock covered the well opening. We met the village executive officer at that site. It seems every village has a person with this title and they look after the affairs of the village, but we are still finding out more about how the management of these villages is set up. On the way back to the office in Babati again, we stopped for a coke (this was lunch!) then stopped at a working water well. This was in a more conventional village with a main street and a few shops and houses. There were a number of adults and children at this well filling up buckets with water from the hand pump. They would then put them on their head and walk back to their homes. The field engineer with us noticed the children were doing short strokes on the pump (almost a dance) so he showed them how to long slow strokes with the pump and get more water.

At night we stayed in a local “hotel” that was inexpensive and nice and clean. They didn’t really have a menu so we asked for chicken and rice with vegetables. The roast chicken came out first but none of the pieces on the plate resembled any chicken we had ever seen before. The chickens here seem to have a lean life as there was no meat on the bones! There was a kitty hanging around and he liked us as we shared this “chicken” with him!

The next day we went back out to the abandoned site as it was to be refurbished that day. So we decided to spend an extra day to help and watch them build a new pump slab and install a pump. There was a local masonry technician there that day to do the concrete works. When we got to site, somehow over night the locals had arranged to drop off a couple of truck loads of sand and some biggish rocks. A number of the locals were there with hammers, pick, axes and attacking these big rocks breaking them down into little pebbles to use in the concrete. There was no other source of gravel around. The first thing was break up the old slab and remove it which didn’t take too long as it looked like little effort had been spent on it in the first place. Then over the rest of the day a new slab was constructed. We didn’t quite get finished so the technician was going back the next day to do the final plastering and install the pump. There is quite a bit to do to make one of these slabs as we learned. We have to think about channelling the spilled water off in the right direction otherwise it gets all muddy around the area and the mud gets tramped back onto the slab. The top of the slab has to be high enough to be above any natural running water the rains cause. There also needs to be a fence around the water source to keep livestock out and to keep kids from using it as a playground.

That night back in Babati, it rained hard. We both woke up during the night and wondered what the road was going to be like in the morning for the drive back to Arusha! It was still very rough and slow but not a mud pool like we thought it might be in places. The side road we had used on the way out, was no longer driveable, as most of it was covered in water. We got stopped by police check points twice on the way back . One said we had to pay a fine for not having a certified copy of the ownership papers with us. We tried to explain we did not know it had to be a certified copy. Then he just waved us on. We were very glad we had Peter with us. (Later in the week we asked Musa bout this and he said it didn’t have to be a certified copy.) Back in Arusha it had also rained and some of the back dirt streets were now potholes full of water.Overall it was a good learning trip for us.

The next day the project leader there and a few others piled us into their Landcruiser and we headed out to the rural villages where the work was being done. She said our little truck may not handle these roads too well. We soon found out why very quickly! They are no roads, only dirt tracks through the scrub and trees that the locals use. No government assistance to make any roads for the people at all. It was dry so it was not too bad, but can’t imagine what would happen when it is wet. The first site we visited was a new well site being drilled. To get a picture of where these are installed, don’t think of a well being installed on a street corner or such but picture an area with rolling hills, no fences anywhere and a well just drilled at some location in a field. (The well sites had previously been sited by a water diviner.)

This location was on the side of a hill. The drillers were a contracting company from Arusha. They were using an older style rig that used percussion or cable tool method. This rig repetitively lifts and drops a weight onto a drill bit down the hole. The bit crushes the rock down to sand like particles. Then every 10 mins of so, they pull the weight and bit out of the hole, lower down a long steel bailer to surge up and down, partially filling it with the newly crushed sand. Then they lift that out and tip it upside down using the winch to dump its contents on the ground. They do this a few times then go back to drilling again. The method is slow compared to other drilling methods but it is lower cost and does not require large air compressors and such. They were down about 30 m deep when we arrived.

The drillers stay on site. They put up a small tent with a “bed” covered by a mosquito net and cook their meals over an open fire. At this time of year it is quite warm but not too hot.

We stayed there about 2 hours to watch their operation. That drilling method was new to us (because it’s not often used in Australia anymore)but the other office staff had seen it all before so they were doing other activities while we watched.

Next we were taken over to a natural spring that had a small flow of coming water from it. It was in some trees on the side of a hill just up from the bottom of the gulley. There was a local woman there getting water in some buckets to take back up the hill to her house, but we had no idea how far she lived from there. It could have been several kilometres away and she was carrying the water. The water out of the spring was clean it seemed but when it ran into a little pool where the buckets were being filled from, it got a bit cloudy. The woman was asked if the water was boiled before it was drank. She said some do and some don’t.

An old abandoned site was the next visit. This was a small (2 m diameter) domed slab that used to have a pump on it, but the pump was gone and a rock covered the well opening. We met the village executive officer at that site. It seems every village has a person with this title and they look after the affairs of the village, but we are still finding out more about how the management of these villages is set up. On the way back to the office in Babati again, we stopped for a coke (this was lunch!) then stopped at a working water well. This was in a more conventional village with a main street and a few shops and houses. There were a number of adults and children at this well filling up buckets with water from the hand pump. They would then put them on their head and walk back to their homes. The field engineer with us noticed the children were doing short strokes on the pump (almost a dance) so he showed them how to long slow strokes with the pump and get more water.

At night we stayed in a local “hotel” that was inexpensive and nice and clean. They didn’t really have a menu so we asked for chicken and rice with vegetables. The roast chicken came out first but none of the pieces on the plate resembled any chicken we had ever seen before. The chickens here seem to have a lean life as there was no meat on the bones! There was a kitty hanging around and he liked us as we shared this “chicken” with him!

The next day we went back out to the abandoned site as it was to be refurbished that day. So we decided to spend an extra day to help and watch them build a new pump slab and install a pump. There was a local masonry technician there that day to do the concrete works. When we got to site, somehow over night the locals had arranged to drop off a couple of truck loads of sand and some biggish rocks. A number of the locals were there with hammers, pick, axes and attacking these big rocks breaking them down into little pebbles to use in the concrete. There was no other source of gravel around. The first thing was break up the old slab and remove it which didn’t take too long as it looked like little effort had been spent on it in the first place. Then over the rest of the day a new slab was constructed. We didn’t quite get finished so the technician was going back the next day to do the final plastering and install the pump. There is quite a bit to do to make one of these slabs as we learned. We have to think about channelling the spilled water off in the right direction otherwise it gets all muddy around the area and the mud gets tramped back onto the slab. The top of the slab has to be high enough to be above any natural running water the rains cause. There also needs to be a fence around the water source to keep livestock out and to keep kids from using it as a playground.

That night back in Babati, it rained hard. We both woke up during the night and wondered what the road was going to be like in the morning for the drive back to Arusha! It was still very rough and slow but not a mud pool like we thought it might be in places. The side road we had used on the way out, was no longer driveable, as most of it was covered in water. We got stopped by police check points twice on the way back . One said we had to pay a fine for not having a certified copy of the ownership papers with us. We tried to explain we did not know it had to be a certified copy. Then he just waved us on. We were very glad we had Peter with us. (Later in the week we asked Musa bout this and he said it didn’t have to be a certified copy.) Back in Arusha it had also rained and some of the back dirt streets were now potholes full of water.Overall it was a good learning trip for us.

Saturday, December 6, 2008

Trying to Do Business in Arusha

One day we went to buy 4 small fittings to extend some plumbing water lines to raise a water tank 2 m. We wanted to gt more pressure at the tap outlets. These were PVC fittings that would take about 1 hour to go buy in Australia including Melbourne traffic. The first obstacle we have over here is we do not speak the language let alone any technical terms. Most people in Tanzania do speak some English at least; otherwise, it would be very difficult to find our way around. We called the shop and through several further calls managed to get the message across that we wanted to come and visit their shop for these parts. The shop is a national company with multiple offices, but they have no email address, no webpage and they do not answer the land line, only a cell phone. The woman was doing her best but we could not understand her too well. Basically she was saying as there are no street names she could not tell us where they were other than in the industrial area. (And we did not know where that was either.) She said come with your driver as she would tell him. We have no driver!! I said I would call her again when we got into the town centre. We did this but we just could not understand her instructions and spent another 45 mins driving around. Finally I asked if she could meet us at the big grocery store, so she did. We then followed her in our truck to her shop. Turns out it is not far off the main street and is a 5 min drive from the town centre. But with no street signs how do you describe your location to someone? Once there I showed her a picture of the fittings we wanted having printed them off a website from a google search the night before. She did not have these in stock but would order them from Dar Es Salam overnight. Now this is about 2 hours later from when we arrived in town.

For the next set of brass hose fittings: The day before, I called a UK guy living here who I hoped would know where to get these parts. He suggested two places on the main street, that we already knew of, and said there were no other industrial type businesses around that would sell fittings. The PVC sales person had also suggested another hardware store on the main street as well. By now we are coming to understand that all the technical items are to be sourced from a short section of the main street of town and if they don’t have them, they are not to be found in Arusha. We drove back to the main street and it is now 1 pm’ish, so all the hardware type stores are closed for the lunch break. They close it seems for about 2 hours. So we went and had lunch too. After lunch back to the hardware stores, there are about 6 of them virtually in a row. I showed them the picture of a ¾” brass hose barb and they just shake their heads like they have never seen one before that big. A couple bought out a ¼” hose barb saying that was all they had. (These are used on compressors which they do carry). So having exhausted all those shops, we drive pass our last hope (which are the two shops the UK guy had mentioned to us.) Still closed for lunch and it is about 3 pm. So we drive back to ADRA. The result of the day was from 11 am to 3:30 we had run around after $10 worth of common fittings and none to be had.

The hardware stores are quite different too. They almost all are a single shop front with a small entrance area about 2 m x 2 m, then a counter with a bunch of bars rising from it up to the ceiling and the sales staff behind the bars. The entrance area has basic items on display like hammers, wrenches, maybe a compressor or a generator. But anything you want, you have to ask for and they tell you if they have it or not. If they do, they go to the back to get it. The back is very crammed and it is a testament to their memory I guess to know what is back there. They do stock common things that may be used on a construction site but anything else, Samehani. (Sorry). There is just no way to browse to see what they have or what else they may have that could do the job as well.

Then begins the problem of finding out who then has parts in another city (which means Dar Es Salam in Tanzania, a 10 hr drive, or Nairobi over the border, a 5 hr drive, in Kenya). Many streets have no names so there are no physical addresses, many of the phone lines have been stolen or neglected so most people are on mobile phones. This means they are not in the phone book. There is no such thing as yellow pages. Most do not have internet so there are no websites to search, let alone find a list of products a company may offer. Any website that does come up for a supplier in Tanzania is normally another search engine site listing Indian or Chinese sites that say they can sell to Tanzania or Thailand etc. Business marketing it seems is all word of mouth only. No one apart from the bigger tourist hotels take credit cards, so it is a cash only based system. There is 20% VAT added to the cost of an item or service too. But you often don’t get a receipt so it makes one wonder about where the VAT is going.

If I do find parts in one of these other cities, I have yet to figure out how to actually pay for them so they will send them. Them I am told if I get them in 2-10 days I would be lucky as I might not get them at all unless I were to use a professional courier service.

10 days later, still no sign of the PVC fittings so I cancelled them and succumbed to the convention used here which is to use galvanised steel pipe and a plumber out on site to manually thread the pipe as needed. But we got the job finished and raised the water tank 2 meters and indeed did get more pressure out the taps.

For the next set of brass hose fittings: The day before, I called a UK guy living here who I hoped would know where to get these parts. He suggested two places on the main street, that we already knew of, and said there were no other industrial type businesses around that would sell fittings. The PVC sales person had also suggested another hardware store on the main street as well. By now we are coming to understand that all the technical items are to be sourced from a short section of the main street of town and if they don’t have them, they are not to be found in Arusha. We drove back to the main street and it is now 1 pm’ish, so all the hardware type stores are closed for the lunch break. They close it seems for about 2 hours. So we went and had lunch too. After lunch back to the hardware stores, there are about 6 of them virtually in a row. I showed them the picture of a ¾” brass hose barb and they just shake their heads like they have never seen one before that big. A couple bought out a ¼” hose barb saying that was all they had. (These are used on compressors which they do carry). So having exhausted all those shops, we drive pass our last hope (which are the two shops the UK guy had mentioned to us.) Still closed for lunch and it is about 3 pm. So we drive back to ADRA. The result of the day was from 11 am to 3:30 we had run around after $10 worth of common fittings and none to be had.

The hardware stores are quite different too. They almost all are a single shop front with a small entrance area about 2 m x 2 m, then a counter with a bunch of bars rising from it up to the ceiling and the sales staff behind the bars. The entrance area has basic items on display like hammers, wrenches, maybe a compressor or a generator. But anything you want, you have to ask for and they tell you if they have it or not. If they do, they go to the back to get it. The back is very crammed and it is a testament to their memory I guess to know what is back there. They do stock common things that may be used on a construction site but anything else, Samehani. (Sorry). There is just no way to browse to see what they have or what else they may have that could do the job as well.

Then begins the problem of finding out who then has parts in another city (which means Dar Es Salam in Tanzania, a 10 hr drive, or Nairobi over the border, a 5 hr drive, in Kenya). Many streets have no names so there are no physical addresses, many of the phone lines have been stolen or neglected so most people are on mobile phones. This means they are not in the phone book. There is no such thing as yellow pages. Most do not have internet so there are no websites to search, let alone find a list of products a company may offer. Any website that does come up for a supplier in Tanzania is normally another search engine site listing Indian or Chinese sites that say they can sell to Tanzania or Thailand etc. Business marketing it seems is all word of mouth only. No one apart from the bigger tourist hotels take credit cards, so it is a cash only based system. There is 20% VAT added to the cost of an item or service too. But you often don’t get a receipt so it makes one wonder about where the VAT is going.

If I do find parts in one of these other cities, I have yet to figure out how to actually pay for them so they will send them. Them I am told if I get them in 2-10 days I would be lucky as I might not get them at all unless I were to use a professional courier service.

10 days later, still no sign of the PVC fittings so I cancelled them and succumbed to the convention used here which is to use galvanised steel pipe and a plumber out on site to manually thread the pipe as needed. But we got the job finished and raised the water tank 2 meters and indeed did get more pressure out the taps.

Subscribe to:

Posts (Atom)