We are at the end of the drilling phase of the project. It has been a fun and very interesting three months. The drillers have been a great crew and we’ve had many a laugh along the way with them even though there are big language differences. It all adds to part of the fun. The next steps are to pump test the wells at various depths to see at what depth we will need to set the pump intake to allow a sustainable pumping rate that the villages will do with these hand pumps. Somewhere around 500 lph we think or in villager terms 25 buckets per hour. The driller told us they will pump a lot less than that as these women spend all their time talking!

Then after pump testing we need to finish off the concrete block slabs that we make to mount the hand pump on and it also serves as a elevated platform for the women to pump upon and keep the pump area out of the mud that will inevitably collect around any place where there is spilt water. This activity has been somewhat going on in parallel with the drilling. The local engineer has been mostly looking after this construction with Nik (see scratched Eye posting below) our neighbour and helper. The slabs are self draining and the water is ducted away a few meters to the low ground side of the slab to keep it away from the pumping area. Finally we put a wire fence around the slab a couple of meters out with a wire gate at the end to keep the livestock out and from contaminating the area. (The fence is made of 2” pipe for the posts and 1” pipe for the post stays and apparently there is a risk of someone stealing them for their scrap value.) Go figure.

The last step will be to actually install the pumps themselves. This will (should) be a short job but the procurement process in Tanzania is very slow. Let me say it starts with at least a 4 week process to first get a original proforma invoice from the supplier for the goods you want, then apply for a VAT tax exemption from the government Tanzania Revenue Authority. The proforma has to be an original no fax or email copies so you have to physically drive to that supplier to get the invoice even if they are a 10 hour drive away then after that is the procurement process, there are no credit card purchases, there are bank transfers but errors here are common. Cash is the medium of choice in a lot of cases so that means driving back to the supplier to give them the cash and hope they have the good in stock otherwise it is yet another trip back to them. (Yes you can tell the government makes it very difficult to make tax exempt purchases as they want to collect as much VAT as they can even through it means groups who are trying to help the people in their country are having to pay over 20% more for the goods they need to do their aid work in Tanzania.) Another Go figure!So there is no planned dates for when pump installation will happen which is a shame as the villagers are excited now about getting these water pumps working having seen us out drilling wells in their villages. When they don’t get it you can guess who will get the blame, yes the mzungus.

Bore water quality is becoming an issues, lab results show high chloride content, over the Tanzanian standard so this has to be considered somehow.

We have drilled 3 wells in each of 4 villages, drilled 1 and will repair two existing wells in a fifth village, 1 well each in the 6th and 7th villages. We were to do more but the budget can only go so far. Originally we were to drill on average 17 m deep wells using the information we had been given by the water diviner who had last year located the sites to drill at. However once we started we found this was far from sufficient and we had to drill on average 55 m depths. This is a much higher cost as the drilling costs roughly on average $100 per meter. After just 5 successful bores and 3 dry ones we were about to run out of money and have to stop. The operations manager of the drilling company we are using, who is from Oregon, paid us a visit and came up with a different and lower cost drilling method to suit us. This was to use a smaller diameter down hole hammer so it would penetrate a lot faster, using less labour time and fuel to drive it, plus since our holes are in rock, not clays he said we could not use PVC to case the hole, just leave the hole walls open and put the pump drop tube down the rock hole. He also said the water will be there just have confidence and drill deeper. This we did and had 100% success rate on all the future bores. Plus we were able to get the project budget revisited and dropped some other items that were no longer considered going to be of importance, so this freed up some funds to go to more drilling. Hence between all of this we got a 2nd wind to go drill more holes and managed to drill the above. So we should get to 17 of the original 22 water sites for the villagers. It has been a challenge from many angles but good to get through to be near the target.

It would have been good to use the philosophy we had for the last 3 villages in the earlier villages. In the early villages we were very conscious of the budget and shy about going deep. Hence some wells have low measured flow rates, below what we had hoped for but at that time it was all we could afford to do. Knowing now that there probably was more water deeper down it would have been good to try to get that. We drilled right at the end of the dry season so we concluded if a well had some water now, then it should yield more water in more wet seasons. Another theory we applied early on was if we measured a well to have a low inflow rate, (called a seep well) then we would drill a little deeper and put the pump inlet at the bottom. Then every night the well would fully recharge up to the static water level, and when the women come in the morning to get water they will fill the first 10-12 buckets from the water column in the bore alone, before having to wait and pump at the slower well recharge rate. Better than no water well at all we determined.

Ramona has done an excellent job of recording all details we use on site. We have to often go back through her notes and to recall what happened back then. She says she doesn’t understand drilling at all, but to read her notes implies the opposite. We made up an excel sheet that we updated as we finished a well. It records, well name location, projected depth, actual drilled depth if drilled, drilling method, drill costs, static water level, in flow rate, salinity level, pH, the type of pump we anticipate using on that bore and to what depth to set the pump inlet. It ends up being a lot of data.

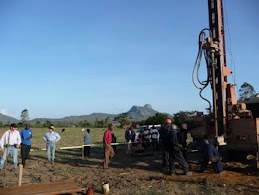

It takes about 3 days to drill a well on average, a day’s travel to and from along these dirt roads/tracks, a day or a day and a half to drill depending on the depth and then a day to complete the well and pack up again. If it rains or we get a break down it adds to this time. So for the last 3 months we’d start the day with waking up to babies (there are many here) in neighbour houses crying, chooks cackling around outside the house, roosters having a crowing competition and some pigs screaming somewhere. Breakfast, then driving our little Pajero to the current site where the drillers were (they usually camped on site in the trucks), start drilling by 9-10 am, drill or work till about 6 -7pm and head back to the house, getting there at 7-7:30. Ramona packed us a picnic lunch every day with a couple of big bottles of cold water and a couple of sodas too. The drillers would do the actual drilling work or a few times we jump in and help lift rods around if one of the crew was away. Mostly though we were observing the drilling, measuring flow rates, static water levels, and making decisions as to keep drilling or when to stop drilling.

The weather for the most part has been fabulous. Glorious sunny days, too hot if anything, just light clothes and a big sun hat. Little wind. We did get 1-2 weeks of days where it would rain in the afternoon for a few hours then stop. This was not too big of a factor but what was a big factor was it making the ground too soft for the truck to move around on without getting stuck. For a while there we spent many hours every 3rd day digging one or other of the trucks out of the dirt. But then it cleared up again to more very nice weather. It made being on site quite pleasant some days. On the south and west are mountains to look at, there are big granite rock out crops spread around which are pretty and fun to spend a few hours climbing on. Some villages have more trees than others which makes them nice. Sometimes we were in or on the edge of a maize field or in the middle of grazing grounds with shepherds around with their live stock of cows and goats. (Alas there are no longer any wild animals around). There were always from a few to 100’s of spectators around. Lots of children(watoto menge!).

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment