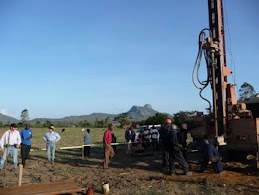

This week we made some good progress on the project. The drill rig arrived on Monday and started drilling Monday after noon. We had made a plan to drill 2 of the 22 bores before Christmas. The reason for this was that the site survey that had been done indicated the depth to the water table at each location. The average depth was 17 m according to this water diviner. Some were only 6 m and some were 30 meters and even one at 55 m. The drillers had had some experience in a nearby region and there they had said they had to go over 100 m deep to get water. This was causing us concern as if we had to drill to similar depths our budget would be blown in the first 6 bores and the villagers would not be happy with us.

The first well called for a depth of 22 m. We saw moist sand start to come up at 16 m. At 22 m there sand was still moist but very little water, we continued to 24 m deep assuming the 22 m depth was to the top of the water table. This was a little better but the driller was shaking his head that there was still no real water. By then it was late and they said let’s stop and see where the water table ends up at by the time we come back in the morning. The next morning using the new Dip meter kindly donated by Heron Instruments (www.heroninstruments.com) and a big bailer donated by Biolab (www.biolab.com.au), we made some level measurements. The water level had risen back all the way up to 7.3 m. We did some bail down tests to try to estimate recovery rates, but being an uncased hole it was difficult for the dip meter probe to not get covered in a slurry and start sounding off. The water flow rate still looked low however, so we decided to drill to 33 m. At around 28 m the materials coming out of the hole were now a real slurry showing it was getting quite wet down there. The driller would purge the hole completely every now and again with the compressor and a lot of water would fly out of the hole. We had a large crowd of spectators lined up outside the exclusion taped zone the drillers had put up. These were the local villagers hoping we would find water there for them to start using. When water would fly out of the hole they would laugh and jostle each other around with big smiles. The driller foreman started to dance a little jig too. At 33 m we stopped and did more drawdown tests and the water level meter showed there was a good amount of recharge coming into the well. Much more than what a villager on a hand pump could pump out so we were happy we had made the right call to drill deeper than the 22-24 m original target depth. The drillers then cased the hole by inserting 5” PVC casing and screen from the bottom to the top. Once the PVC was fully in, they filled the annulus between the bore ID and the PVC OD with fine gravel for the gravel pack then a cement plug on top of that up to the surface to prevent any surface water from running down the side of the PVC and contaminating the groundwater from the formation. The top was finished off with a 8” steel casing about 1.2 m long inserted around the PVC casing. We asked them to leave 400 mm of the steel casing sticking up above the ground, ready for us to build a concrete slab around it and mount the hand pump on top of that. Since we were not going to do the slab before Christmas, the drillers said what they normally do is weld on a plate on top of the 8” casing. This prevents children who think they are playing from coming and throwing rocks down the PVC and destroying the well.

The next day while the drillers were packing up and moving to the next site we had to drive into Morogoro to get the missing items for the house so that could be finished up ready for us to move into as we were still in this little hotel room which is getting uncomfortable as there is no where to spread our affairs out. The target depth at this second site was 15 m. It was in the same village as the first well, Ukwamani, but about 1 km (0.6 m) away. The drillers sent a text at noon saying they were at 15 m and the cuttings were dry, what do they do? We sent them to 24 m hoping it was the same situation as the first well. Later that afternoon they sent a text saying a small amount of water was flowing in at 16 m, but at 24 m it was hard rock that appeared unfractured. They were going to stop for the night and see where the water level would rise up to overnight. The next morning the water level had come up to 6.25 m from the surface. The driller was saying this was then the same water table as the first well. The flow rate into the well was still low so we decided to drill to 30 m to see if we could get into fractured rock as we had the day before. No such luck. At 30 m, still hard rock and no rock fractures were coming out of the bore only small sand like ground up rock particles. We stopped going deeper and they blew all the water and slurry out of the hole. We then did a remeasure of the water flow rate into the well by following the rising water level in the bore. It was the same as previous which showed that no water was coming in from these deeper zones but from that 16 m zone only. We calculated the rate to be about 200 liters per hour. The village women carry 20 liter buckets so that is 10 buckets an hour they could pump from this bore. I asked the driller if he thought the people could pump 10 buckets per hour. He started chuckling and replied with that these woman use the time at the well site as socialising. They pump a few strokes then stop to chat, then pump a few more strokes and so on, so no they would not be filling 10 buckets an hour. So taking that with a grain of salt, we decided to stop for this well and come back after Christmas to finish off developing and installing the PVC and steel top outer casing. The drillers packed up and late that afternoon caught busses out to their respective home towns for Christmas.

The next day with Jacob we went out to the list sites that we had not seen as yet and made notes about them as to their accessibility for the drill rig, or if any of the site markers the water diviner had placed were too close to each other to make it not worth putting in all wells at those locations. We also looked at the results of the drilling of the two wells and concluded that we would have to add an extra 8 m of depth on average to every bore we planned to drill to be more confident we would strike water and have a deep enough hole to fully insert the intake of pump drop tubes under several meters of water. We wanted to then see how this would affect the drilling budget. Jacob was also getting carpenters, masons and electricians into connect up the items we had bought in Morogoro to finish off the house. We hope it will be finished this weekend so we can move in when we come back after New Year.

We are off next week to visit the Selous Game Reserve and to Kilwa a coastal town to see some old Arabic ruins and hopefully find a resort or two to hang out in for a few days.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment